Zinc furnace engineering

Covering the full range from wire surface preparation and galvanizing itself right through to recycling – Jasper combines expertise across the entire galvanizing process chain with experience and quality in furnace and machine engineering. Our products stand out above all for efficiency, long service life and adaptation to custom requirements. Off-the-shelf products are one thing. We develop the perfect solution that meets your individual needs and conforms to your precise specifications.

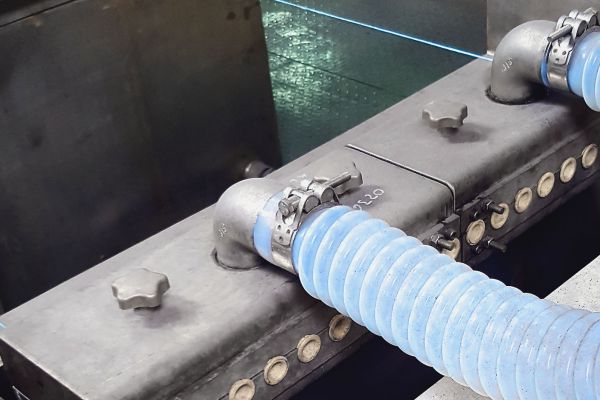

Wiping Systems

Uniform coating thicknesses: Both for commercial coating and heavy coating applications, our wiper systems for wire production ensure uniform coating thicknesses and minimal zinc consumption.

Lead Burning Bath

Improved zinc coating: A clean wire allows improved zinc coating. Jasper lead burning baths enable a longer kettle service life due to indirect energy input.

Zinc Dross Distilling Furnace

Environment-friendly recovery: Zinc dross can be recovered and used. Our distilling furnace recovers up to 88 percent of the zinc contained in zinc dross with 99.9 percent purity.

Drying Furnace

Individual solutions: Our drying furnaces are available with a ceramic lining or concrete casing. Both of these ensure an improved surface and consistent product quality.

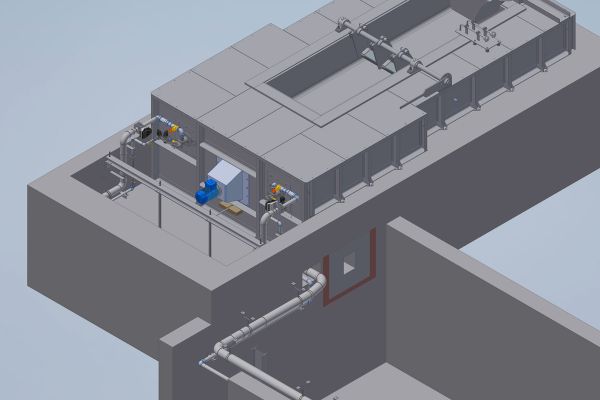

Galvanizing Furnace

Unlimited service life: With zinc bath temperatures up to 620 °C, furnaces with a ceramic kettle permit extra-low operating costs because special shaped bricks with cooling channels lastingly prevent damage from diffusing zinc.

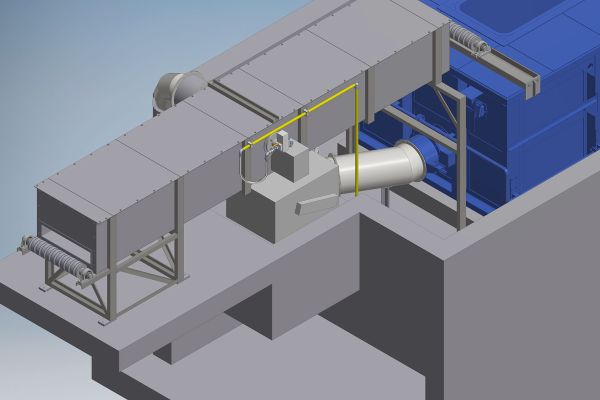

Galvanizing Furnace

Maximum efficiency: By using flat flame burners, our steel kettle furnaces attain up to 75 percent efficiency and ensure even and gentle heating.