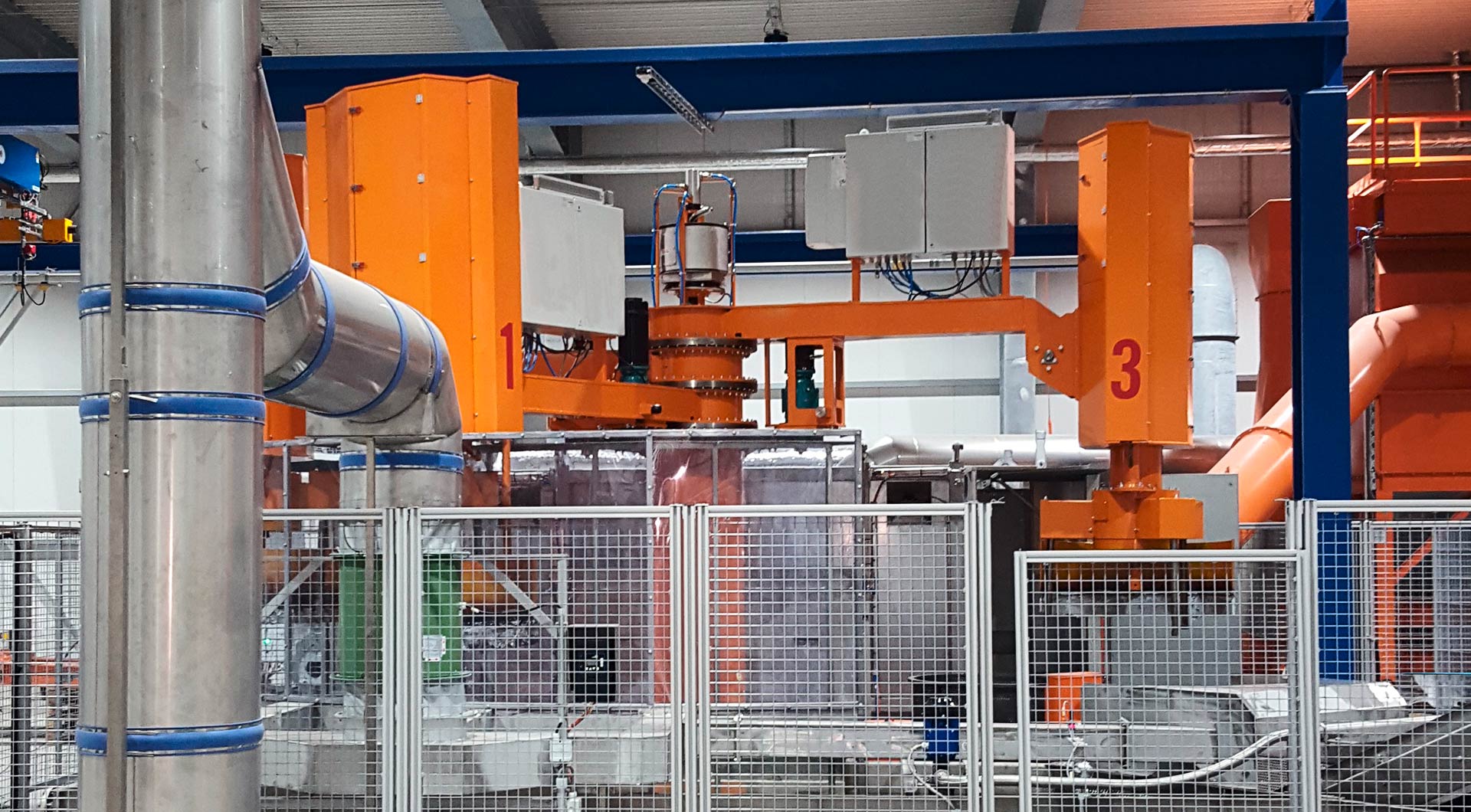

Zerberus©

Automatic Galvanizing Machine for Small Parts

Application

The machine economically coats small parts and bulk materials in large quantities. It guarantees an even thickness of the zinc layer and reduces the costs of material, energy and rework at the same time.

High Throughput

With a powerful furnace and fast, automatic handling of the baskets and racks, the system achieves a throughput of up to 5t (!) per hour. At its heart is a handling system with three arms, which automatically carries out all operations between filling and emptying the baskets. Baskets and racks are picked up, immersed in the zinc bath, centrifuged and transported to the water bath for quenching.

No manual intervention is required during the entire process.

Gentle Galvanizing

With bolts, the gentle handling avoids damage, so that threads do not have to be rewound. There is no need for time-consuming reworking, which previously entailed a considerable cost burden.

Efficiency

The regenerative or recuperative burner system reduces energy consumption by up to 30 percent compared to other systems. Since the burners are never operated with excess air, up to 70 percent less zinc ash is produced. This significantly reduces material consumption and the cost of ash removal.

In addition, the galvanized parts are free of impurities because the surface of the zinc bath is automatically cleaned of zinc ash before the basket is immersed and after boiling.

Product sheet Zerberus – Automatic Galvanizing Machine for Small Parts

Download (PDF)