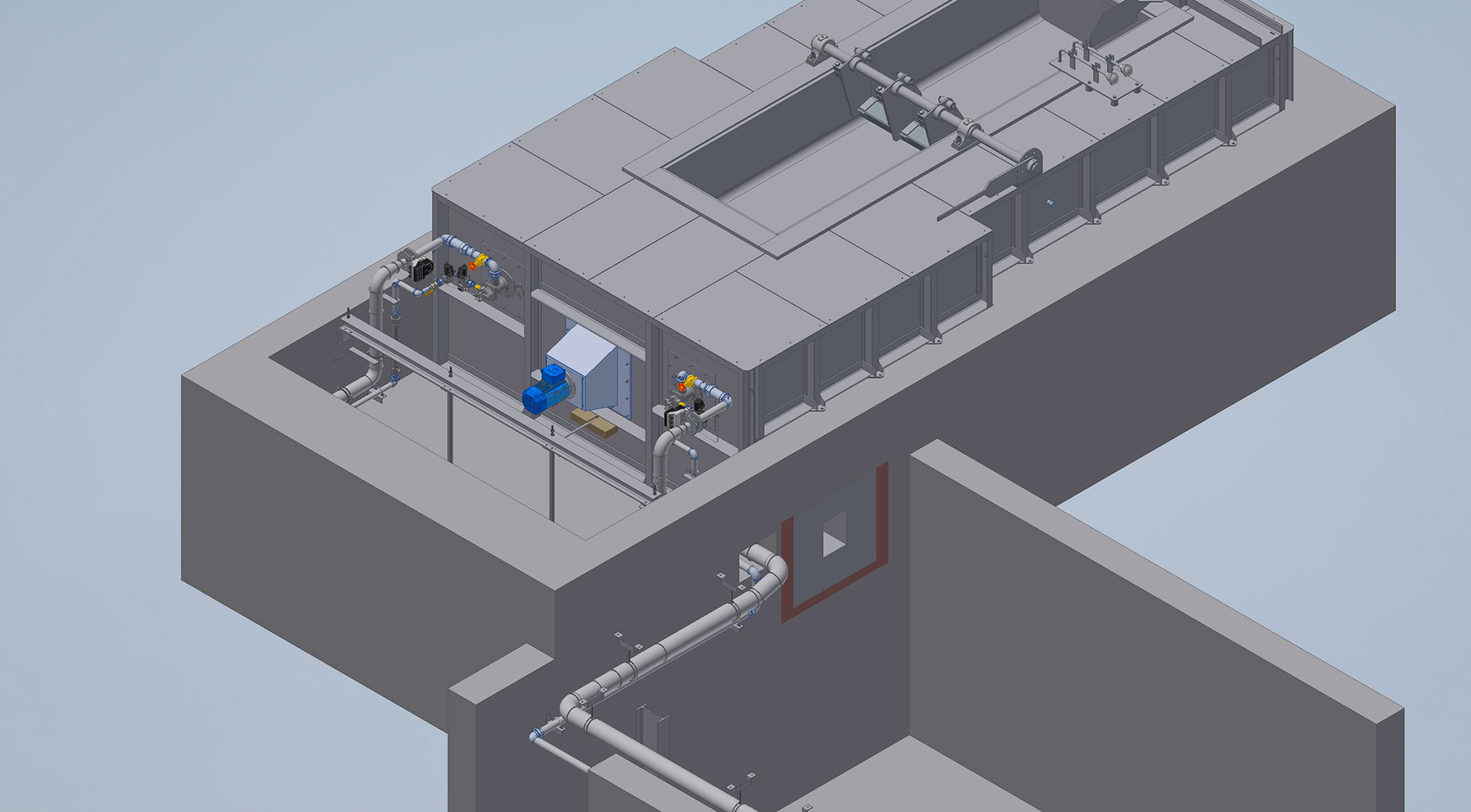

Lead Burning Bath

Efficient Pretreatment

Construction

Steel construction with ceramic lining. The hot air of the burner is led through channels around the kettle. There is no direct flame contact with the kettle. This leads to an increased service life.

The Process

Oil residues are removed from the wire before it enters the pickling line. The guidance is achieved in the immersion bath via a ceramic immersion stone. At the inlet and outlet this is done by rollers.

Benefits

- An improved zinc coating is achieved

- Consistent product quality

- Long kettle service life

- Improved economic efficiency

Technical Specifications (Example)

Dimensions

- Length: 6,150 mm

- Width: 3,400 mm

- Depth: 1,615 mm (partly below ground)

Process parameters

- Operating weight: continuous process

- Daily capacity: ca. 2,000 kg/h

- Temperature: ca. 450 °C

Heating

- Natural gas/oil: 2 x 180 kW

Consumption

- Gas: 30 Nm³/h

Product sheet Lead Burning Bath

Download (PDF)